For most supply chain managers, production planning becomes an onerous task as the stakes are high, and knowing what and how things should be done is extremely crucial. Proper evaluation and measuring every step in a long production process is necessary for managers; to maximize efficiency, minimize waste, and save time and money.

From regulating work at the very first procurement of raw material to managing all the resources with precision, – efficient production planning ensures that everything is utilized and no stone is left unturned.

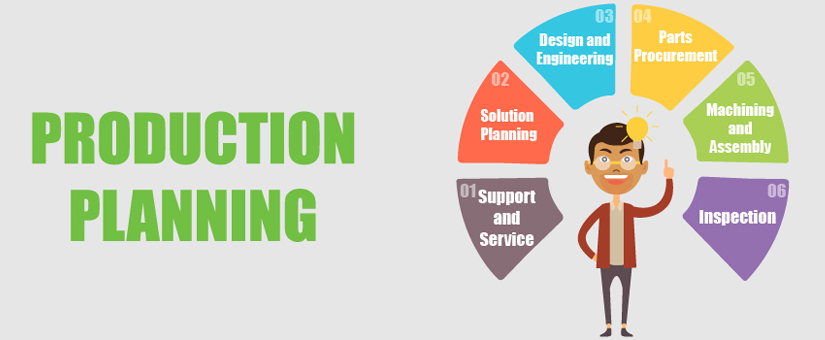

Here is what production planning typically entails:

Production planning—how it ensures efficiency and accuracy?

Sometimes, even a slight deviation from the existing production plan can translate into massive losses, which is why employing an efficient production planning system as a watchdog is so important. A production planning system calculates the size of each resource, maintains the production flow, arranges prompt adjustment in case of emergency and finally, ensures timely delivery.

Zenscale production planning software—taking efficiency and accuracy to the next level

Zenscale production planning system is based on the two pillars of production planning –accuracy and efficiency, which is what most supply chain managers strive for while maintaining production chains and remains elusive.

With the integration of ERP, manufacturing/distribution, and time tracking software into a single unit, this laser-edge production planning software ensures that managers no longer need to spend long hours in planning their next moves.

Features:

-

Tracks information in real time: Tracks and troubleshoots errors in real time and facilitates seamless production flow.

-

Eliminates manual errors: Eliminates the most commonly occurring human entry errors in production planning and helps in achieving optimum stock control with ease.

-

Optimize and tracks production: By providing 360 degree visibility over supply chains, it ensures that manufacturing management becomes a breeze for managers (often considered as the most difficult part of the job).

-

Enables supply to meet demand: By getting inputs via forecasting, the integrated ERP software helps managers control production of material in accordance with the demand.

-

Updated information and Product Configuration: Once the supply and demand needs are accurately met after a single product life-cycle, the information is updated accordingly for the next stage.

Benefits

- Facilitates continuous production flow

- Determines sequence accurately and succinctly

- Build future production programmers

- Co-ordinate work schedules seamlessly

- Maintains inventories efficiently

- Evaluates performance flow

- Tracks and prevents loopholes